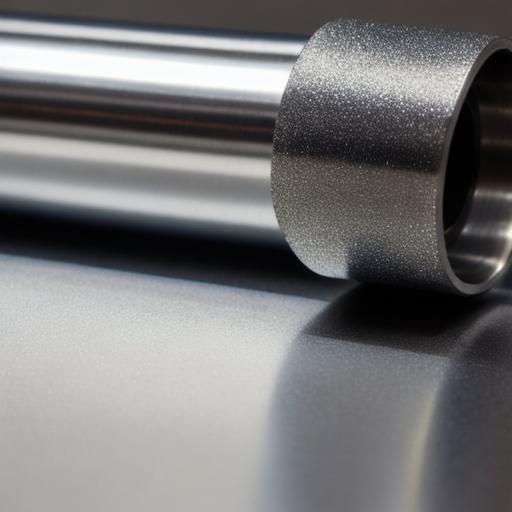

Bead blasting, also known as shot peening, is a highly efficient and advanced technique used to clean and prepare stainless steel for painting or refinishing. It uses small metal beads to remove layers of paint, rust and other contaminants from surfaces. Bead blasting produces a smooth, uniform finish that is free of defects and imperfections, making it ideal for use in automotive, aerospace, and other industries where appearance is critical.

Efficiency is one of the main reasons why bead blasting is becoming the go-to method for stainless steel preparation. It can remove up to 99% of paint, rust, and other contaminants from a surface in just a few minutes, saving time and reducing labor costs compared to traditional methods such as sandblasting or hand sanding.

Choosing the right beads is also crucial for achieving the best results. Aluminum, steel, and glass beads are available, and the choice depends on the surface being worked on and the level of abrasiveness required. Adjusting the pressure at which the beads are propelled can also vary depending on the task at hand, and it’s important to wear protective gear when using a bead blaster.

Some common questions about bead blasting stainless steel include what is the difference between bead blasting and sandblasting, can bead blasting damage the surface, and what type of beads should I use for stainless steel. These questions are answered in detail, along with tips and techniques to help get the most out of your bead blasting experience.